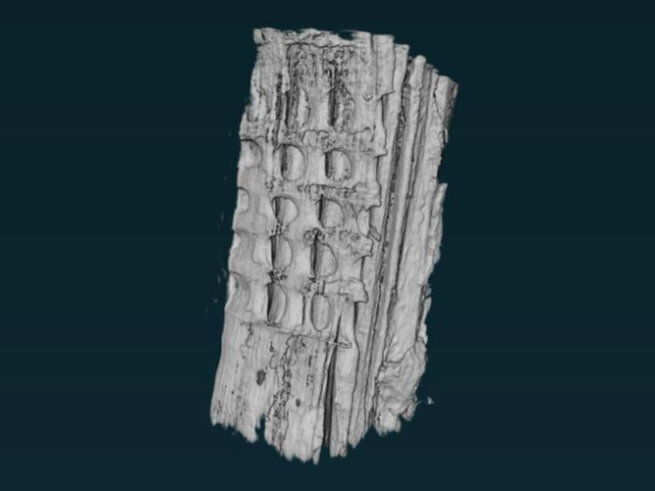

Whether for packaging, plastics or new materials, manufacturers are increasingly turning to wood as a sustainable raw material. However, anyone wishing to develop new wood-based products must have a thorough understanding of its structure and properties. That is why researchers at the Thünen Institute of Wood Research and the University of Hamburg have developed a new sample capsule in which they can examine natural materials under strong X-ray radiation. The radiation makes tiny three-dimensional structures in the wood samples visible – but without protection, it would destroy the samples.

The path from idea to implementation was long: for their investigations, the researchers travelled seven times to a synchrotron facility – a state-of-the-art facility that uses particularly powerful X-rays. Measuring time there is precious and is allocated in 24-hour shifts, so sleep is often a secondary concern. Added to this was the coronavirus lockdown: delivery problems with components from China, repeated staff absences due to false-positive coronavirus tests and an overall reduction in team size made the work even more difficult.

"We worked there in long shifts and with extreme sleep deprivation on equipment costing tens of thousands of euros – a lot can quickly go wrong if you're inattentive for just a moment," says Martin Nopens, a scientist at the Thünen Institute of Wood Research.

After five prototypes, the job is done: the new sample capsule, measuring around ten by six centimetres, is ready for use. Inside, the temperature and humidity remain stable during measurement, ensuring that the samples remain intact. It can now also be used in other fields of research, such as pharmaceuticals and polymer research.

For their project, the Thünen researchers were able to examine their samples at the German Electron Synchrotron (DESY) in Hamburg – and received active support on site from the experts at the Helmholtz Centre Hereon. In return, the newly developed sample capsule will remain at the measuring facility for future projects. Incidentally, researchers at synchrotron facilities worldwide enjoy a special status: once their application has been approved, the measurements are free of charge for them. Industry, on the other hand, pays more than £1,000 per hour for the measurements.