Expertise

The situation in poultry keeping

Jochen Hahne | 30.06.2022

Poultry keeping has increased significantly in the last years. Poultry meat is low-cost, low in fat, healthy and its consumption is not restricted by religious taboos. The per capita poultry consumption increased from 12.4 kg (1989/1990) to 18.5 kg (2011/2012). But the increase in poultry keeping in Germany also results in environmental impacts via the emission of odorants, ammonia, particulate matter and bio-aerosols (Fig. 1).

Against this background we develop techniques for the cleaning of exhaust air from poultry keepings. The main problem in this connection is the large air volume flow which is required to meet the animal welfare demands within the stable and must be cleaned. In a typical broiler house with 40,000 full grown heads, a volume flow of 240,000 m³/h can occur during the summer time. These large volume flows result in a short residence time in the exhaust air treatment system. It makes matters worse that many typical odorants in the exhaust air of poultry keepings are hardly water soluble and therefore hardly open to washing-off. Particulate matter contributes to blockages of air scrubbers.

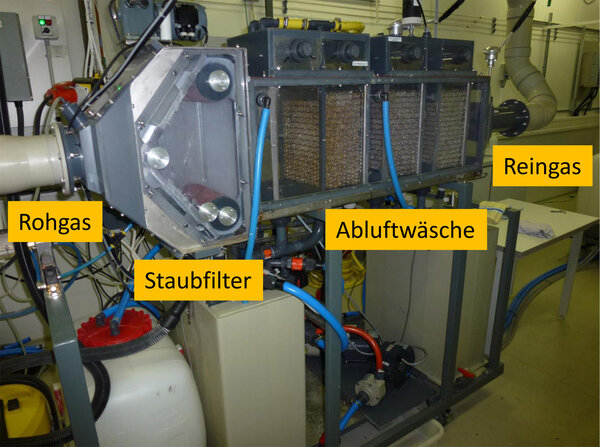

Therefore it is aim of the work with different test facilities (Fig. 2) to develop an effective upstream dust removal and an increased odor reduction under practical conditions to economically feasible conditions. The upstream dust removal unit consists of a filter fleece to separate coarse particles. The pressure drops increase during this operation. The pressure drop is controlled and in the case of exceeding a set point, automatic working fleece regeneration starts with fleece cleaning and dust removal in a manageable form. The main advantage of upstream dust removal: Downstream process units will be protected against blockages and loss of operability.

![[Translate to English:] Durch die Größe der Ställe und den hohen Tierbesatz entsteht viel Abluft mit unerwünschten Emissionen.](/media/_processed_/e/5/csm_Bild8_Huehnerhaltung_57db741a01.jpg)

![[Translate to English:] Logo des Bundesministerium für Ernährung und Landwirtschaft](/media/allgemein/logos/BMEL_Logo.svg)