How can the valuable and renewable raw material wood be used even more efficiently? We conduct research to ensure that wood is used optimally from a building material to a natural chemical raw material.

Raw materials and manufacturing processes influence the properties of wood-based products and their impact on people and the environment. It is therefore necessary to further develop technologies, products and their alternatives and to assess them on a scientific basis. This comprehensive expertise is necessary for objective assessment and scientific advice for politics, business and society. It is also a prerequisite for innovations in the bioeconomy and for our work on environmentally friendly products and processes.

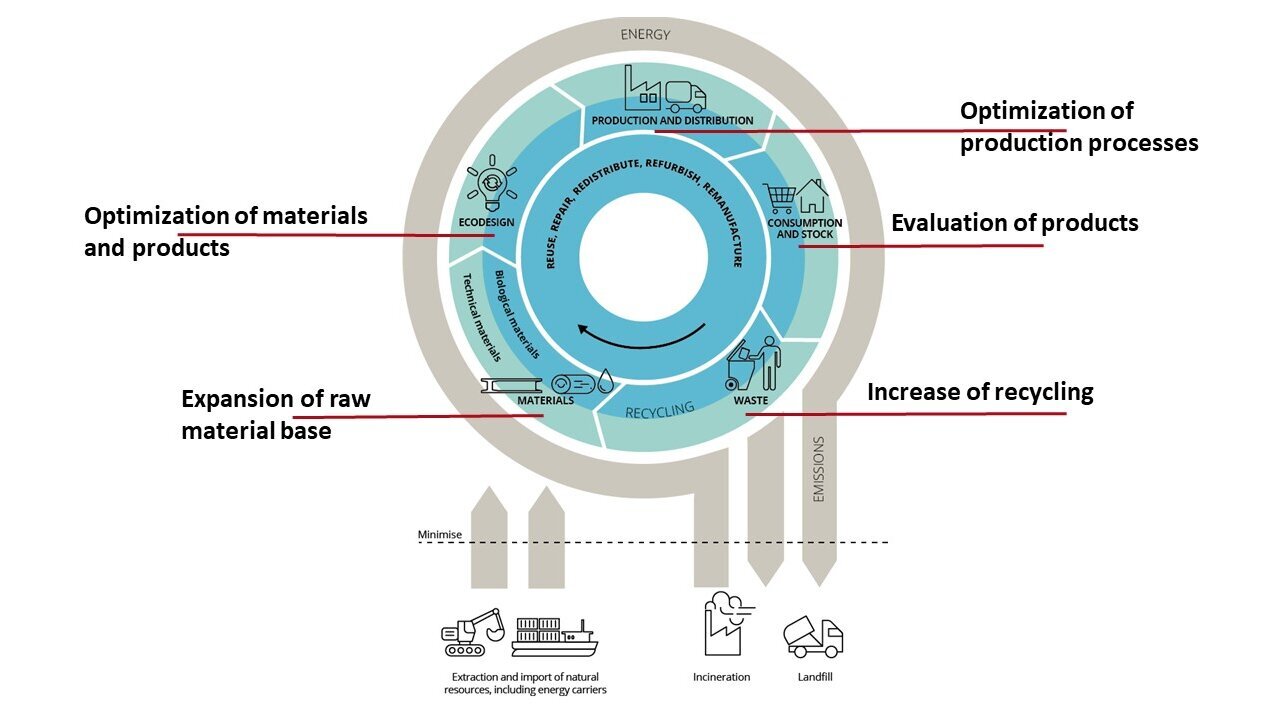

A societal challenge is to use wood economically and efficiently and to improve its availability through recycling and cascade use. We are therefore researching how to make wood and its components as well as by-products and by-products of wood-processing processes fully usable and to keep the carbon bound in the wood in the material cycle for as long as possible. In the work area, solutions are therefore developed for the following key topics:

Efficient and high-quality material use of wood and other woody plants requires optimal production methods for wood-based products. There are major challenges in the production of wood-based materials, but also in the production of fiber materials for paper and waste paper applications and the development of higher-quality lignin products, as often only low-quality raw materials are available or the production processes are too complex.

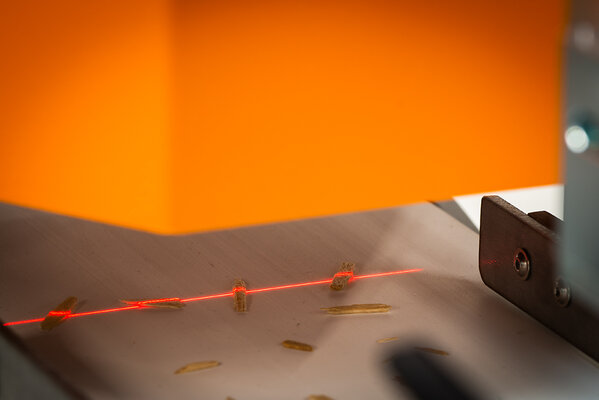

The development of laser-based three-dimensional particle measurement and process integration into chipboard production is intended to enable, for example, optimized use of the raw material and the prediction of the material properties before the pressing process.

As the flow of high-quality fiber material into waste paper recycling is declining sharply, reinforcing materials are required. We are therefore researching the environmentally friendly production of reinforcing fibers for packaging papers containing waste paper and using grain straw as an alternative raw material.

The ongoing implementation of the EU circular economy package and the European Plastics Strategy means that increased efforts need to be made to avoid, reuse or recycle packaging waste. Lignin-based packaging and coating materials could be used as an alternative to common plastics. Therefore, the simplified production of lignin derivatives by reactive extrusion was investigated.

The focus of our work is the complete, sustainable and optimal use of all wood components. We conduct research in interdisciplinary teams along the entire value chain, from raw materials to the extraction of valuable materials to the product and the possibilities for reuse and recycling.

The spectrum of work ranges from the development of efficient extraction processes for the production of valuable wood extractives, the use of extractives for innovative paper coating, the investigation of gentle pulping processes for the production of reinforcing fibers for waste paper, to the testing of wood fibers as a substitute for peat in plant substrates.

Alternatives to petro-based adhesive types are being tested with new approaches to the formaldehyde-free production of lignin-based binders from renewable raw materials. One focus is work on the use of lignin, a by-product of pulp production. The properties of the lignin are specifically adapted to the requirements of adhesive synthesis. In order to be able to meet the increased demands on the functionality and environmental compatibility of binders in the future, lignin-based polyurethane adhesives and foams are being investigated, the use of health-critical isocyanates can be dispensed with in their production.

We also strive to maximize wood components in a variety of applications, with a focus on exploring opportunities to increase and optimize the use of reclaimed wood in wood products. How this can help reduce waste and increase the efficiency and cost-effectiveness of using wood is the subject of current research projects.

To conserve fossil raw materials, many products can be replaced with renewable raw materials, especially wood and wood components. Lignin, which is produced in large quantities during pulp production and is usually burned, can also be used as a material. The aim of a current research project, for example, is to modify lignin so that the intermediate products can be used to produce formaldehyde-free lignin-based wood adhesives.

In the research project Biomimetic plasma polymers for the functionalization of paper, the suitability of pyrolysis oil, tall oil and biogenic precursor molecules for increasing the durability of paper is being investigated. The aim is also to test methods for obtaining suitable precursor molecules and to test the recyclability of the coated papers.

We are investigating the suitability of wood fibers as a raw material for use as a plant substrate in the “HoFaTo” project. This development aims to reduce the extraction and use of peat in order to reduce carbon dioxide emissions into the atmosphere in the long term. To do this, the microbial degradability of the wood fibers is reduced to enable longer use in horticultural applications.

Through increased material recycling and the recycling of waste wood, valuable raw materials can be recovered and used in new products. The raw material wood therefore remains in use for a longer period of time. The social dialogue and quality assurance project in the use of recycled wood along the value chain (waste wood dialogue) examines the questions: How do consumers deal with the topic? Is it even attractive for companies to develop new business models? And would a change have a long-term positive effect on our raw material supply? This is intended to promote cascade use by the end consumer through the use of products containing recycled wood, where appropriate, and to derive recommendations for action for political processes.

A circular economy is already largely established for paper production. Packaging papers in particular are often made from 100% recycled paper. In recent years, however, there has been an increasing search for raw material alternatives to the classic pulp made from wood and the waste paper produced from it. There are therefore increasing attempts to produce fibers from agricultural by-products such as straw or fiber plants grown specifically for this purpose such as hemp or miscanthus (giant miscanthus) and use them for paper production. Aim of our research project Environmentally friendly production of reinforcing fibers for packaging papers containing waste paper. The influence of these fibers on the recyclability of papers is an important area of investigation in order to establish and maintain a functioning circular economy.

The circular bioeconomy is an innovative approach that aims to use biological resources sustainably while minimizing waste. In order to successfully implement this approach, clear recommendations for action are essential.

We develop recommendations to support companies, governments and other actors in the timber industry in integrating the circular bioeconomy into their business practices. This includes measures to promote circular processes, reduce waste and increase efficiency in the use of biological resources, especially wood.