Project

BioButanol

Integral Evaluation of a biotechnical process for the production of butanol from agricultural residues or raw materials

Butanol is an important chemical feedstock used in paints resins, plasticizers and polymers. The aim of the project was the integrated evaluation of a biotechnical process for the produktion of butanol from agricultural residues or raw materials .

Background and Objective

The classical butanol processes of the early 20th century were mostly based on molasses. Since the sugar content of molasses decreased continuously due to better extraction technologies and the prices at the same time increased, the biotechnological process couldn’t compete with the upcoming chemical synthesis from fossil fuel after the second world war. For economic reasons the last running plants (South Africa, Russia) were switched of in the 90s of the last century.

Aim of the economic study is to develop a generic assessment framework for converting renewable materials in Germany; this framework will be exemplarily applied to the butanol value chain.

Approach

The goal of the project was to develop and evaluate several technologies for the efficient and economic production of butanol from agricultural raw materials as well as residues.The operations are divided into 4 main work packages:

- Processing of raw materials and residues, as well as product separation

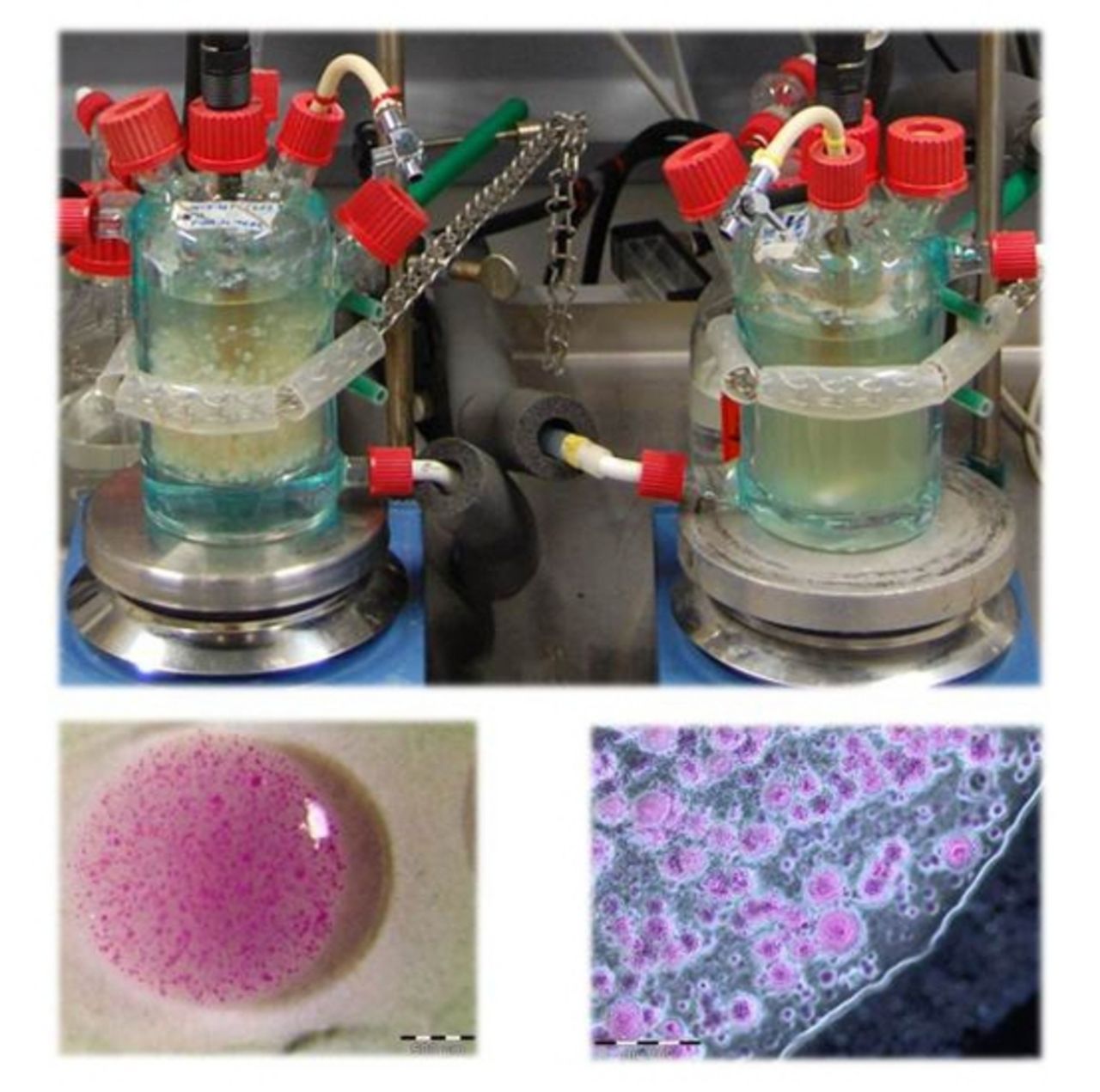

- Bioconversion, including genetic engineering (screening, strain development, metabolic) and Fermentation

- Life cycle assessment and eco-balancing

- Economic evaluation

The economic and ecological assessment should be positioned along the whole value-added chain, as well as the analytical adoption and optimisation.

Our Research Questions

Optimization of an integrated process for the production of butanol from renewable resources. Due to the high toxicity of the product (n-butanol) the achievable concentratiion is limited to about 16 g/L. How can we establish an economical process?

Results

To obtain an industrial economical bio-process for butanol production, sugar concentrations of 60 g/L or more are necessary. To keep the costs low and to avoid competition with food and feed production, a promising agricultural residue was investigated. Wheat chaff, the dust-like side product of wheat harvest is a low cost lignocellulosic feedstock which yields of80 g/L of fermentable sugars after optimal pre-treatment and hydrolysis.

The genetic engineering was focused on typing of promising bacterial strains and optimisation of product composition. The development of genetic tools and the construction of vectors and transformation protocols in vito could be completed successfully, but the physiological aim, to switch of acetone production and thereby increasing butanol concentration in vivo could not be demonstrated.

The fermentation costs could be reduced by means of medium optimisation. The by-product hydrogen plays an important role in the metabolism of Clostridium saccharoperbutylacetonicum and has to be taken into account to achieve a stable process, e.g. by providing a constant partial pressure of hydrogen during fermentation. Wheat chaff and sugar beet could be fermented successfully. Extraction of butanol was achieved with Isofol®12, a less toxic, branched alcohol with a partition coefficient of about 5. An alternative is adsorption to active charcoal (e.g. Norit PK 1-3 at 126 mg/g) but additional research is required in this field.

The economics of biotechnical production of butanol depend strongly on feedstock costs and product marketing. The source of fermentation substrate and energy for product separations accounts for the environmental impact. Due to the low value of fermentation substrate, storage and transport mainly influences the price. At the current situation in Germany the biotechnical production of butanol is neither economical nor ecological competitive to the fossil fuel based butanol.

Involved Thünen-Partners

Duration

6.2010 - 12.2013

Publications to the project

- 0

Anders N, Ellsiepen S, Hellert J, Kaufmann C, Prüße U, Schubert M, Stichnothe H, Storz H, Willke T, Vorlop K-D (2014) Schlussbericht zum Vorhaben : Ganzheitliche Bewertung eines biotechnologischen Prozesses zur Herstellung von Butanol aus agrarischen Rest- und Rohstoffen - Phase 2. Bonn: Bundesministerium für Ernährung, Landwirtschaft und Verbraucherschutz, 105 p

![[Translate to English:] Logo des Bundesministerium für Ernährung und Landwirtschaft](/media/allgemein/logos/BMEL_Logo.svg)