Project

Biotechnological production and electrochemical downstream processing of fumaric acid

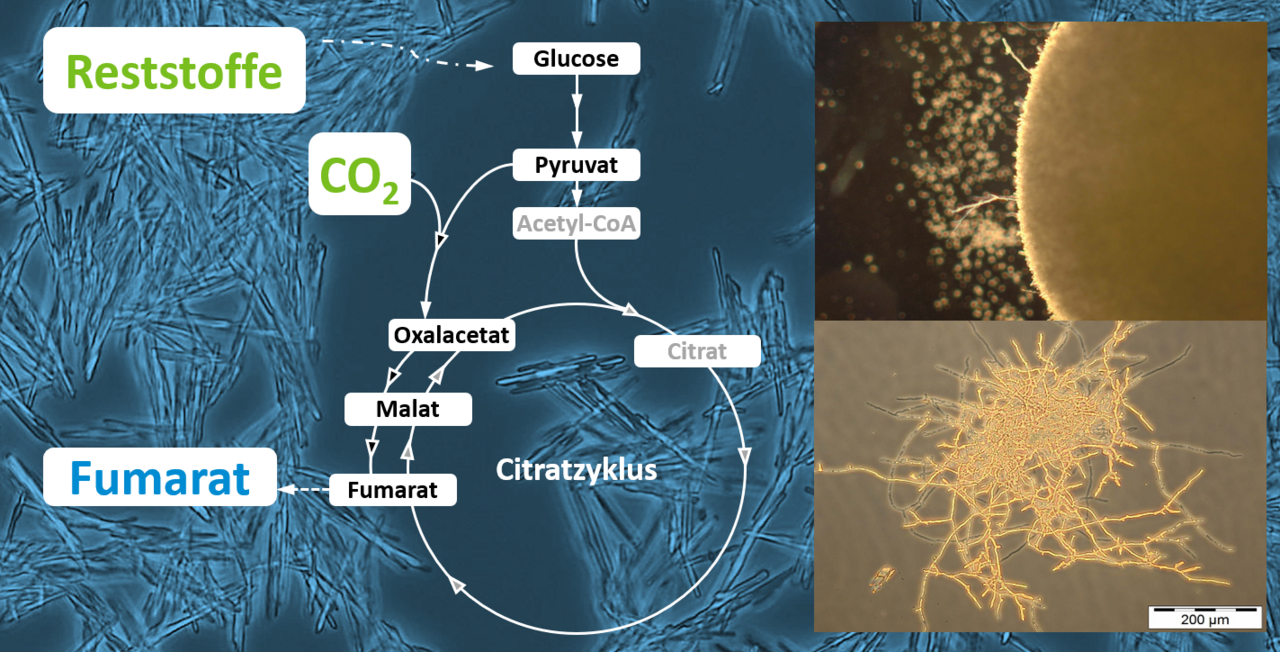

Electrochemical downstream processing of fumaric acid with CO2 incycling to increase the biotechnological carbon yield

A building block for achieving a climate-neutral economy is the increased use of renewable instead of fossil raw materials. Biotechnological processes, such as the biotechnological production of fumaric acid, play a key role here.

Background and Objective

Fumaric acid is an unsaturated dicarboxylic acid and a major building block of the chemical industry. It is currently used in polymers, pharmaceuticals, and food and feed, and is considered as one of the most potentially important biobased chemicals. Biobased fumaric acid production using fungi was carried out since the 1940s, but was displaced by the emerging petrochemical industry. Today, fumaric acid is produced exclusively petrochemically from fossil feedstocks.

Switching back to renewable feedstocks as the starting material for this chemical would conserve remaining fossil feedstocks, reduce CO2 emissions, improve the current carbon footprint, and contribute to the transition to a bio-based circular economy. To achieve this goal, the biotechnological route for fumaric acid production is of particular interest.

In our completed ERA-IB collaborative project "Fumaric Acid for Polymer Applications (FAPA)", we investigated the fermentative production of fumaric acid using R. arrhizus NRRL 1526 and glucose as carbon and energy source. In particular, we were able to significantly increase the final concentrations of fumaric acid to 195 g/L. Based on these results, we are investigating the integration of fermentation and downstream processing in this project in cooperation with RWTH Aachen University and Südzucker AG. Upstream and downstream are to enable selective fumaric acid separation and reduced base use with the aid of electrochemically induced pH shift, which will lead to a significant increase in the fermentative performance indicators of biotechnologically produced fumaric acid. In the case of fumaric acid, there is also the possibility of using CO2 as a co-substrate in addition to biogenic substrates via reductive metabolism of the microorganism, which can increase the biological carbon yield and consequently reduce the area required to produce the organic raw materials. For the same reason, side streams of existing production processes that have not been utilized to a high degree to date will also be used for fumaric acid production. The biotechnological conversion process will be designed to be sustainable and cost-effective

Approach

The Thünen Institute of Agricultural Technology will develop and optimize the biocatalytic process for the production of fumaric acid by increasing the carbon yield and using sugar-containing side streams. Furthermore, the co-substrate CO2 will be used for the fermentation. A 4-fold parallel bioreactor as well as several process bioreactors (5-15 L) are available for the investigations of physicochemical parameters, the use of immobilized biomass as well as the scale-up. In addition, the fermentation will be optimized and modeled. After scale-up, the fermentation will be operated continuously in order to interconnect it with the electrochemical downstream process at RWTH Aachen University.

Thünen-Contact

Involved Thünen-Partners

Involved external Thünen-Partners

-

RWTH Aachen

(Aachen, Deutschland) -

Südzucker AG

(Mannheim, Deutschland)

Funding Body

-

Fachagentur Nachwachsende Rohstoffe e.V. (FNR)

(national, öffentlich)

Duration

1.2023 - 9.2026

More Information

Project funding number: 2221NR041B

Funding program: FNR

Project status:

ongoing

Publications on the project

- 0

Wilhelm J, Kuenz A, Prüße U (2025) Biotechnological production of fumaric acid by Rhizopus arrhizus. In: Himmelfahrtstagung on Bioprocess Engineering 2025 : From genes to products ; 26 - 28 May 2025, Atlantic Hotel Universum Bremen ; Book of abstracts. p 110

- 1

Wilhelm J, Kuenz A, Prüße U (2024) Biotechnological production of fumaric acid by Rhizopus arrhizus NRRL 1526 [Poster]. In: Himmelfahrtstagung on Bioprocess Engineering 2024 - Novel strategies and technologies for sustainable bioprocesses and bioproducts : 6 - 8 May 2024, marinaforum Regensburg.

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)