Biotechnological production of itaconic acid

Itaconic acid is one of the most promising precursors for biobased plastics. We were able to increase the final itaconic acid concentration by a systematical optimization of the process and decreasing the cultivation time simultaneously.

Because of the particular structure of itaconic acid, it is used in different fields of plastics: the production of resins, binders, paint, carpets and coatings. The industrial production is performed by the cultivation of the filamentous fungi Aspergillus terreus. The organism converts in an aerobic cultivation the carbon source sugar to itaconic acid. Although this process is performed since the 1950s, the costs of it are still too high in comparison to similar products produced by petrochemical industry. Amongst other reasons, this is because the final itaconic acid concentrations and productivities are still too low.

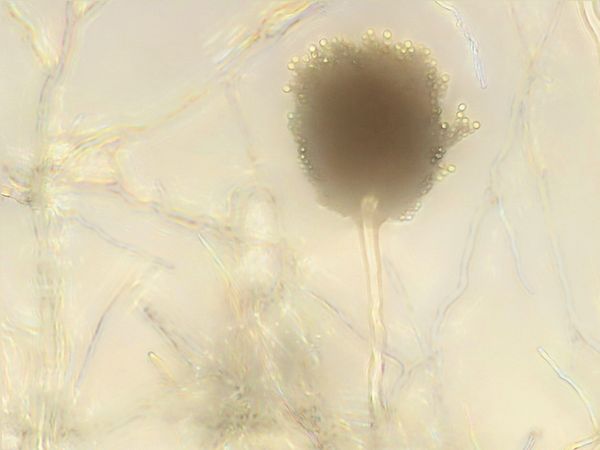

At our institute we have longstanding experience with this fermentation process. By constantly improving the process conditions and medium composition we were able to develop a stable platform for the itaconic acid production with Aspergillus terreus. The formation of small pellets (Ø 0,1 mm ) reduces the viscosity of the fermentation broth and avoids an oxygen limitation inside of the pellets.

By skilled process optimization we were able to increase the itaconic acid concentration to 146 g/L. The media composition as well as the pH of the cultivation plays an important role in this. While increasing the final concentration we were also able to reduce the cultivation time by about half.

The production of conidia usually is performed by surface cultivation, which is elaborate and needs large areas. We were able to induce the conidia formation of Aspergillus terreus in submerged cultivation. This enables an easier scale-up of the production process. In addition to that the conidia had a shorter germination phase, which reduces the cultivation time and thereby increases the productivity.

There is a good chance, that the achieved improvements will decrease the costs of an industrial itaconic acid process. The increase in the product concentration will make the purification of the itaconic acid more cost-effective, while the higher productivity halves the cultivation time. This will make itaconic acid an even more important biobased precursor for plastics.