Project

Biobased Dicarboxylic Acids

Development of eco-efficient processes for the production of biobased dicarboxylic acids for polyester synthesis

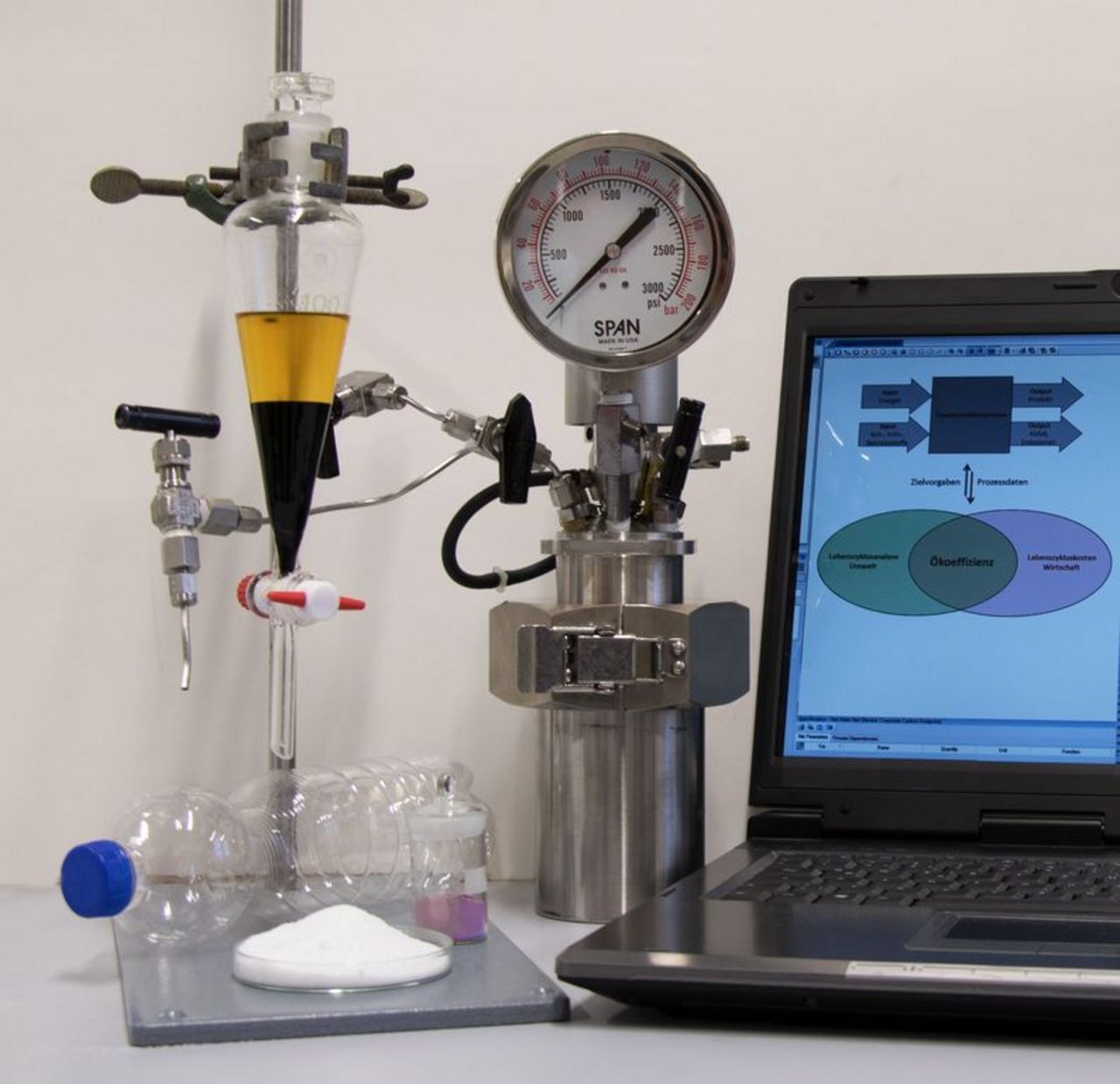

Biobased dicarboxylic acids auch as furan dicarboyxylic acid (FDCA) are interesting building blocks for polyesters. In this project the process development will be supported by eco-efficency analysis, which may be suitable to guide the development of similar processes for the production of biobased chemicals.

Background and Objective

Every year approximately 50 million tons of fossil-based PET (polyethylene terephtalate) are produced worldwide, with rising tendency. In a ranking of the most produced plastics worldwide PET occupies position 4. The most promising candidate for replacing polyethylene terephthalate is the bio-based polyethylene furanoate (PEF), because of its structural similarity. In comparison to PET, PEF exhibits even better properties. Due to the lower gas permeability, PEF protects beverages more effective against atmospheric oxygen than PET. Furthermore, the fizz lasts longer, as CO2 does not exhaust so quickly.

The predominant PEF component, the furan dicarboxylic acid (FDCA), can be obtained in a simple reaction from 5-Hydroxymethylfurfural (HMF). A great challenge since several decades is the cost-efficient and effective production of HMF from sugars. Our innovative and patent-pending research approach shall solve this problem and pave the way to a bio-based economy.

Eco-design serves as basis for the integration of ecoefficiency aspects in design, and development processes of products and product systems. Based on life cycle assessment and cost data, Eco-design enables the ecoefficient analysis of design modifications and further development of products at an early stage.

Under consideration of technical and economic and ecological requirements (e.g. material selection and feasibility), the most suitable design options are investigated. In this case, it is crucial to consider the whole product life cycle to prevent a shift of environmental burdens and costs between and within life cycle stages.

Approach

The process development part is based on the results of the project “HMF from sugars”. Main focus of the experimental investigations will be on the separation and purification of intermediate HMF and subsequent furan dicarboyxylic acid. For this purpose, different down-stream processing techniques like adsorption, crystallization and distillation are investigated and the results compared concerning their efficiency and attainable product purity. Afterwards, the received furan dicarboxylic acid and their derivatives respectively are converted with bio-based ethylene glycol to PEF. For this polycondensation reaction, process parameters have to be optimized and the properties of the synthesized polymers characterized.

The process development will be supported by eco-efficiency analysis in order to ensure that cost and environmental aspects are properly addressed at an early development stage.

In order to minimize costs and environmental impacts suitable process options will be investigated regarding their costs, environmental performance and possible trade-offs.

Data and Methods

Ecoefficiency analysis consists of the simultaneous analysis of costs and environmental impacts using a life-cycle approach. We will use UMBERTO-software to conduct the analysis. As far as possible we will collect relevant data directly. Remaining data gaps will be filled either by suitable databases such as ECOINVENT or by scientific literature.

Results

Aim of the project is on the one hand the development of an efficient and economic process for the synthesis of PEF via HMF and FDCA from sugars. This would provide an entirely bio-based alternative for PET, one of the most important petroleum-based plastics.

In addition we aim to develop an ecoefficency based process development strategy for FDCA, which may be directly or after appropriate modification suitable to guide the process development of similar biobased chemicals.

Thünen-Contact

Involved Thünen-Partners

Duration

8.2016 - 7.2019

More Information

Project status:

finished

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)

![[Translate to English:] Logo des Bundesministerium für Ernährung und Landwirtschaft](/media/allgemein/logos/BMEL_Logo.svg)