Project

Production of Succinic acid

Biotechnological Production of Succinic Acid from Renewable Resources

Succinic acid and its salts (succinates) have great potential as a raw material for various products of the chemical industry. A so far unknown bacterial strain seems predestined for the economical production of succinate from renewable resources.

Background and Objective

Succinic acid is a dicarboxylic acid and an essential intermediate in the citric acid cycle, in almost all living organisms. It is possible to produce succinic acid biotechnologically from renewable resources. Beside some fungi and a few bacteria strains, no natural organisms are previously known producing succinic acid in sufficient quantities and under such favorable conditions that a corresponding industrial process compareable to chemical synthesis would be feasible. The aim of this project is to establish an efficient biotechnological process for the production of succinic acid from renewable resources.

Approach

To achieve the objective an unidentified bacterium was isolated from a soil sample. This new isolated bacterium is able to produce succinic acid from renewable resources. The identification and characterization of this bacterium as well as the optimization of growth and production conditions are carried out. Therefor the physical parameters like pH, redox potential, oxygen supply, temperature and media composition, are under investigation. Especially the usage of inexpensive carbon and nitrogen sources based on agricultural raw materials and residues (sugars from hemicelluloses, plant residues, various press cake, glycerol and the like) are from great importance. Finally, it might be advantageous to immobilize the highly productive biomass. For this the biomass will be enclosed in a biocompatible macroscopic matrix in which it lives and produces. Thus, it is possible to use the biomass over several cycles for the production of succinic acid, and it is easy to separate the biomass from the product broth. An additional advantage would be the increased productivity which results from the high cell concentration in the bioreactor.

Data and Methods

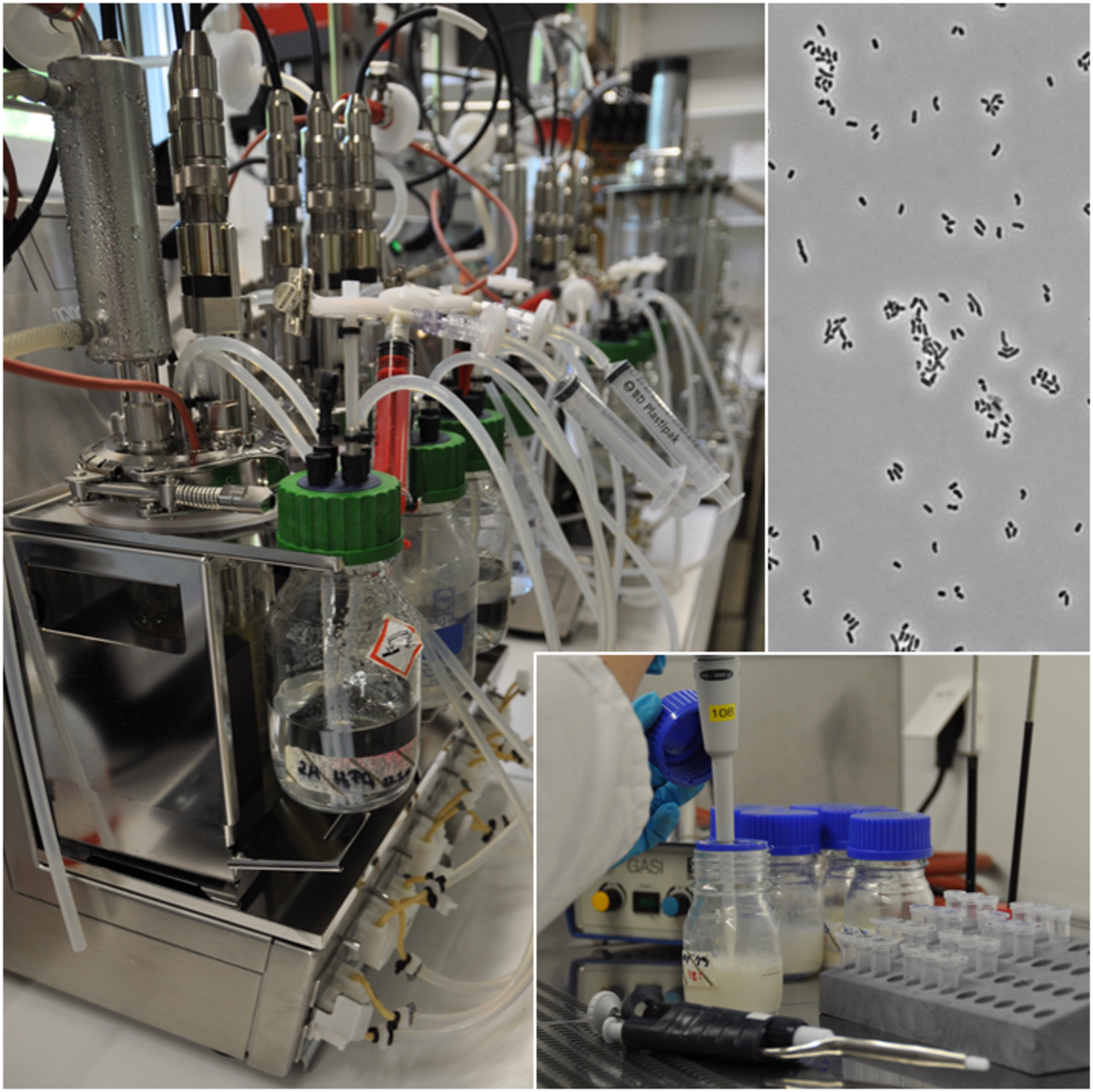

To perform time-consuming strain characterizations and the subsequent optimization experiments in its different aspects, a laboratory robot system for high-throughput screening and media optimization is provided. For the investigations of physicochemical parameters, the usage of immobilized biomass and scale-up a 4-fold multi-bioreactor system and several process-bioreactor (5-15 L) are provided. Regarding the analytic, rapid and semi-quantitative methods are used such as powerful and comprehensive online-sensor, capillary electrophoresis (CE), thin layer chromatography (TLC) and spectroscopy. The precise material analysis for balancing and by-product determination is performed by HPLC and GC.

Our Research Questions

Within the project, such parameters should preferably be processed implementing the outstanding properties of a potential production strain in a technical process. A high level of productivity (P), yield (Y) and product concentration (C) is to be achieved.

Results

Aim of this project is to establish an efficient biotechnological process for the production of succinic acid from renewable resources. Preliminary results in the conversion of glycerol into succinic acid are very promising. More than 100 g/L succinic acid were produced with an yield of 100%, which is only possible if the metabolism uses at least partially the reductive citric acid cycle including CO2 fixation (anaerobic respiration, fumarate respiration ).

The project investigated a previously unknown soil organism for the biotechnological production of succinic acid using glycerol and a carbonate source (magnesium carbonate and sodium carbonate). The soil bacterium was found to be an inseparable mixed culture. For the formation of succinic acid, a new organism belonging to the actinomycetes group was identified in this symbiotic cell group. Under microaerophilic conditions, this mixed culture formed succinic acid with 87 g/L as the main product at a yield of 0.9 g/g and a maximum productivity of 0.66 g/(L∙h). A microaerophilic environment is ensured by cultivation in laboratory glass bottles with a cannula and a septum in the lid. A low daily air supply is additionally ensured by one-time sampling. The working volume in the laboratory glass bottles should correspond to 50 % of the total volume of the bottles. Supplementation of aspartic acid, glutamic acid and phenylalanine as well as the B-vitamin pantothenic acid promotes production.

For bioreactor cultivation it was used both magnesium carbonate and sodium carbonate as a buffer. A suitable gassing strategy could be found. The process parameters pH value, temperature, stirrer speed, redox potential and the influence of the initial glycerol concentration were validated. During fedbatch processes a final succinic acid concentration of 133 g/L was achieved. With growth-decoupled production, yield and productivity reach 1.15 g/g and 0.39 g/(L∙h), respectively.

Involved Thünen-Partners

Funding Body

-

Federal Ministry of Food und Agriculture (BMEL)

(national, öffentlich)

Duration

9.2015 - 10.2018

More Information

Project funding number: 22036214

Funding program: FNR

Project status:

finished

Publications on the project

- 0

Bromann S (2020) Charakterisierung und Optimierung eines neuartigen Bakterienstammes zur Herstellung von Bernsteinsäure. Braunschweig: Technische Univ, Fakultät für Lebenswissenschaften, 128 p, Braunschweig, Techn Univ, Fakultät für Lebenswissenschaften, Diss

- 1

Kuenz A, Hoffmann L, Goy K, Bromann S, Prüße U (2020) High-Level production of succinic acid from crude glycerol by a wild type organism. Catalysts 10(5):470, DOI:10.3390/catal10050470

- 2

Bromann S, Goy K, Kuenz A, Prüße U, Willke T (2019) Schlussbericht zum Vorhaben "BIOBST - BIOtechnische Herstellung von BernSTeinsäure aus nachwachsenden Rohstoffen (Biotechnological Production of Succinic Acid from Renewable Resources) ; Laufzeit: 01.09.2015 bis 15.10.2018. Braunschweig: Johann Heinrich von Thünen-Institut, 92 p

- 3

Bromann S, Goy K, Kuenz A, Willke T, Prüße U (2018) Biotechnische Herstellung von Bernsteinsäure aus Glycerin. Chemie Ingenieur Technik 90(9):1176, DOI:10.1002/cite.201855099

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)

![[Translate to English:] Logo des Bundesministerium für Ernährung und Landwirtschaft](/media/allgemein/logos/BMEL_Logo.svg)