Project

Cheap alternatives to yeast extract in bioprocesses

Substitution of yeast extract in industrially relevant bioprocesses

Yeast extract provides important nutrients, but it is also a major cost-factor in fermentation processes. Our objective is the substitution of yeast extract by agricultural raw materials in order to improve the economic efficiency of biobased products.

Background and Objective

A biobased production of important chemical precursors? With biotechnological processes, lots of products can be produced, but the production costs are high. For a competitive biobased product compared to petro-based chemicals, the production costs need to be reduced. One major cost-factor in lots of bioprocesses is yeast extract. Yeast extract provides nutrients for the growth of various microorganisms and their product formation. Therefore, it is quite a challenge to substitute yeast extract by alternative nutrient sources without a decrease in product concentration and productivity. For this purpose, it is necessary to investigate the individual nutritional requirements of the microorganisms used in the fermentation process and to fulfill these requirements with agricultural raw materials as yeast extract substitute.

In our project “Biotechnologically produced D-lactic acid” we already succeeded in the efficient substitution of yeast extract by agricultural raw materials. Within the scope of this follow-up project, we want build on these results and we will further develop the optimization strategy.

We transfer our knowledge to a broad spectrum of bioprocesses and we investigate the nutritional requirements of aerobic and anaerobic bacteria and fungi, taking as examples the production processes of

- L-Lactic acid

- Erythritol

- 1,3-Propanediol

- 3-Hydroxypropionaldehyde.

These processes are further optimized for the cultivation with alternative nutrient sources in bioreactors.

Approach

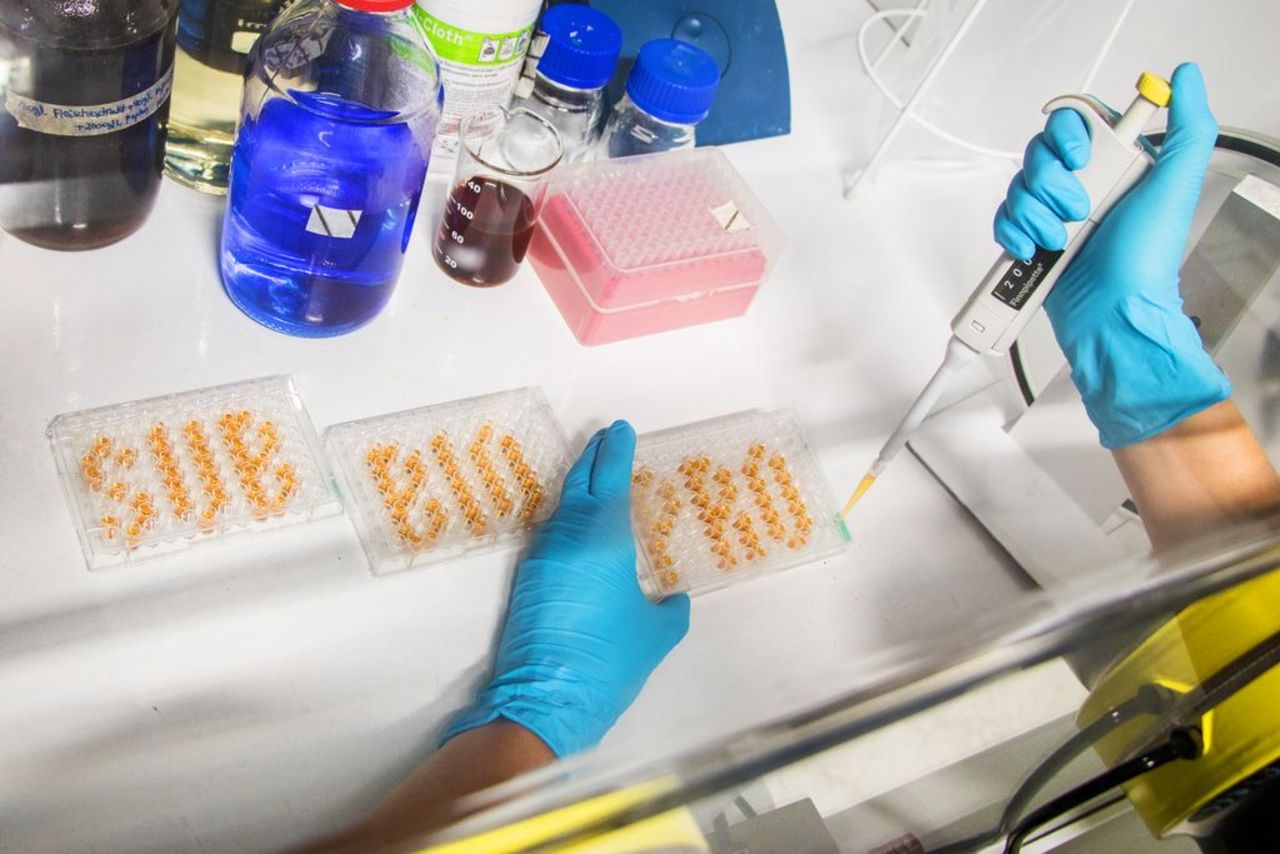

The fermentation is first carried out in microwell plates, where lots of parameters can be varied at the same time. In this way, we investigate and optimize the media composition. Following, the process is scaled up into shaking flasks and bioreactors for process optimization. For this, hydrolysates from raw materials are used as nutrient sources. Finally, we evaluate the cost reduction of the optimized process in profitability assessment studies.

Data and Methods

We use a variety of modern instrumental analysis techniques such as HPLC, GC, ICP-OES und ion chromatography for the determination of media composition and the quantification of product formation.

Results

DOI:10.3220/PB1614600746000

Involved Thünen-Partners

Duration

5.2017 - 8.2020

More Information

Project funding number: FKZ22016816

Funding program: FNR

Project status:

finished

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)

![[Translate to English:] Logo des Bundesministerium für Ernährung und Landwirtschaft](/media/allgemein/logos/BMEL_Logo.svg)